I decided to experiment felting using vehicle components as formers to create shapes in the felt, I knitted the initial fabric on the knitting machine using 100% lambs wool.

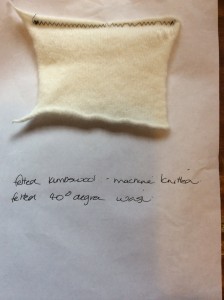

1st felted sample 40 degree machine wash – fabric felted very well – shrinkage approx. 10%

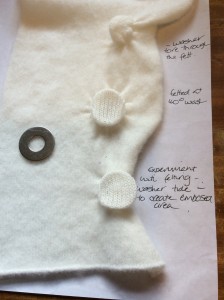

2nd felted sample Yarn used – Lambs wool – using metal washers tied into the knitted fabric

1 washer tore through the felt during the machine wash outcome partially successful

1 washer tore through the felt during the machine wash outcome partially successful

3rd felted sample Yarn used Lambs wool / Viscose thread – metal washer used to create shape

Washers remained in the felt ? addition of viscose created a stronger fabric that prevented the tearing.

Washers remained in the felt ? addition of viscose created a stronger fabric that prevented the tearing.

4th felted sample Yarn used – Lambs wool – Washers fixed in place with elastic bands 40 degree wash

All washers tore through fabric, created an interesting fabric on the reverse but not suitable for the application. ? The addition of towels to the washing drum caused the problem or the use of elastic bands caused the washers to tear the felt.

All washers tore through fabric, created an interesting fabric on the reverse but not suitable for the application. ? The addition of towels to the washing drum caused the problem or the use of elastic bands caused the washers to tear the felt.

5th felted sample Yarn used Lambs wool and Viscose thread – Washers fixed in place with elastic bands -40 degree wash.

Again all washers tore through the felt,? Use of elastic bands or the addition of towels to the washing cycle. Fabric not suitable for application.

Again all washers tore through the felt,? Use of elastic bands or the addition of towels to the washing cycle. Fabric not suitable for application.

Learning to take forward

Continue to experiment with materials

Small changes can cause difficulties during the making process, again reduce the variables by changing 1 thing at a time

Research “Shibori” felting

Research artist using manipulated surfaces