I was very lucky to be able to use the Print Room after the unit hand in day as I had a 2 week unit extension, I had the print room to myself, again many thanks to both Neil and Yasmin the technical staff in the print room who where both really helpful.Having the print room to myself enabled me to spread out and take over lots of space.

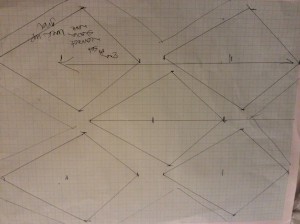

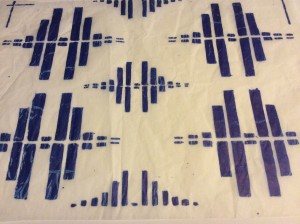

I wanted to create a repeat diamond pattern( using the graphs to create the diamond) inspired by a piece of furniture cloth I had seen at the Castle Study Centre, I initially marked out the outline on graph paper to work out the diamond size, added the diamond repeat.

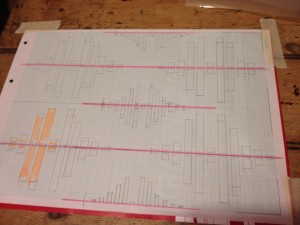

I wanted to create a 3 colour repeat inspired by the colours in the Norwich Shawls, I had difficulties with the screens as 2 of the repeats where on the same screen resulting in a large screen. I had not given the edges of the screen much thought when creating the koda traces and the edges where very uneven, also the patterned layers of koda trace overlapped in places.

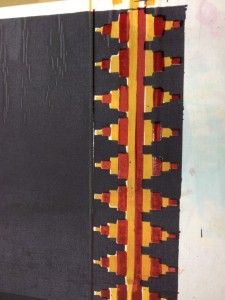

I wanted to use black, red hopefully a madder red as in the shawls, royal blue and gold.

I decide to use Blood Red which was not very successful as it had no depth and no richness, the gold was too rust/brown I remixed the dye using 50% Lemon yellow and 50 %Antique Gold, the Royal Blue worked well.

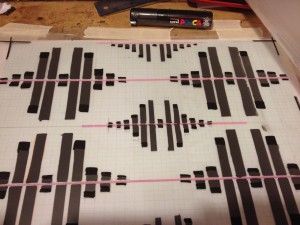

Experimental print onto tracing paper, I really like the effect.

Experimental print onto tracing paper, I really like the effect.

I tried to print the screens in repeat, this didn’t work at all, the screens where not aligned , the screens slipped, in terms of printed outcomes this was a disaster but in the terms of learning I gained so much knowledge from the print session-

Kodatraces MUST be accurate with clean edges (only if that is the desired effect)

Patterns MUST match Accuracy (again only if that’s what is required)

Repeat Furniture should be used

Edge of repeat should be measured

Colours should be thoroughly tested washed and steamed before deciding on final colour choice

The print area should be checked for foreign objects, I didn’t notice this staple until the dye hit the staple.

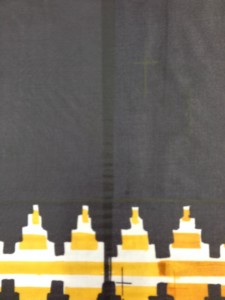

The second screen print was more successful but again I had similar difficulties with the printing process, this design was inspired by the borders of the shawls and the mitred corners of the shawls.

Screens not lining up and slipping

Screens not lining up and slipping

Learning to take forward —

Think about the out come wanted- do I want a precise finished pattern with straight clean edges if so THINK about what is required, measure, use a ruler . This may not be for me or that screen printing may not be able to give me the required outcome if not try another process or develop Patience.

If not work with my strengths